The Ultimate Guide To Motorcycle Parts New Zealand Specialists

Table of ContentsThe Best Strategy To Use For Motorcycle Parts New Zealand SpecialistsMotorcycle Parts New Zealand Specialists for DummiesMotorcycle Parts New Zealand Specialists Fundamentals ExplainedIndicators on Motorcycle Parts New Zealand Specialists You Need To KnowSome Known Details About Motorcycle Parts New Zealand Specialists Things about Motorcycle Parts New Zealand SpecialistsThe Only Guide for Motorcycle Parts New Zealand SpecialistsThe Ultimate Guide To Motorcycle Parts New Zealand Specialists

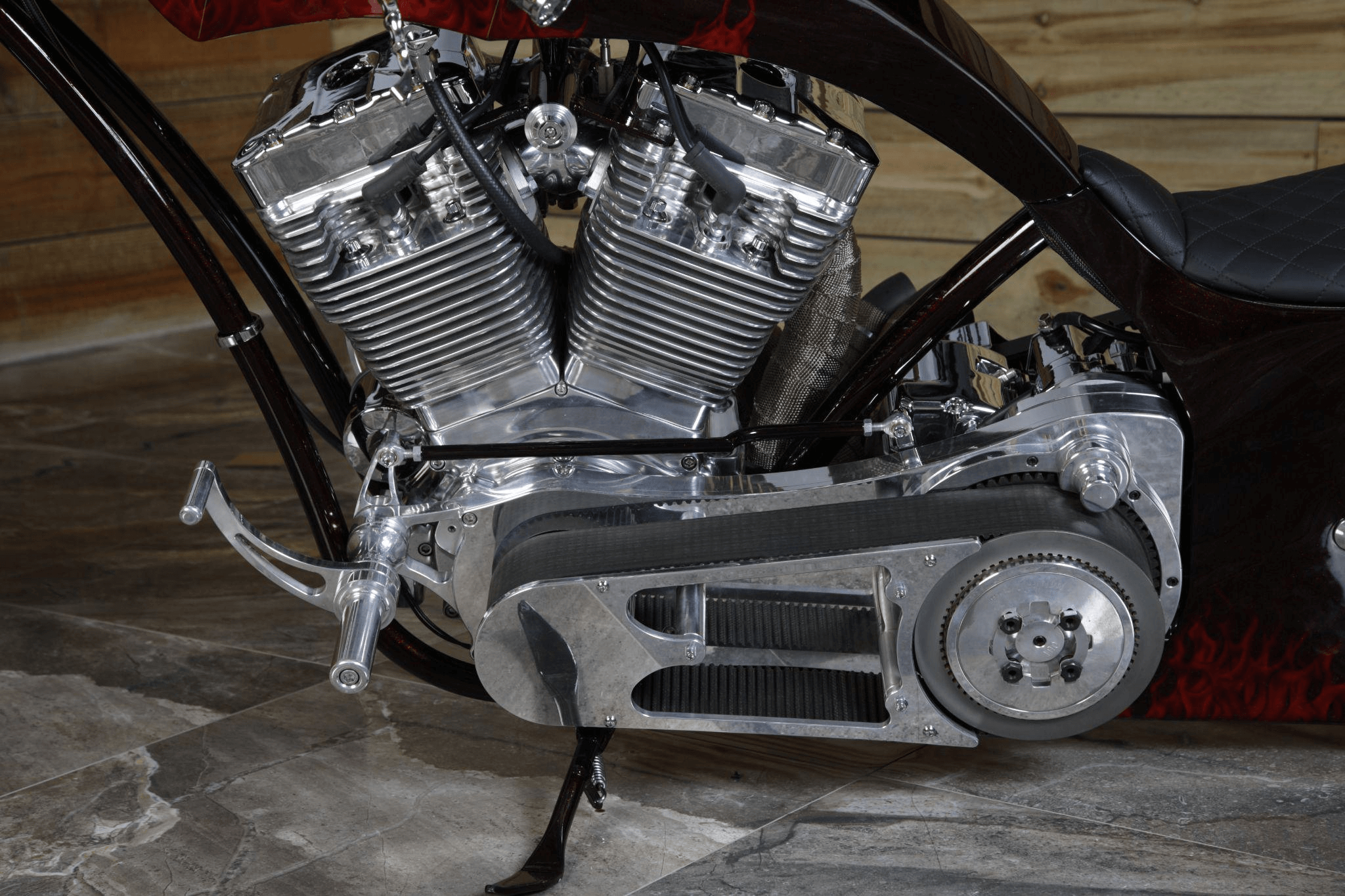

So, connect to one of our professionals today.CNC machining technology is rapidly becoming the centerpiece of several production processes around the globe as a direct outcome of its several advantages over various other techniques. Additionally, the industries that manufacture motorcycles have gotten on board with this trend. One of the most innovative business are currently developing their engine elements and wheels making use of machining techniques originally created for motorbike parts.

You may be questioning why we utilize. Currently that we have your focus allow us explain the rationale behind this contemporary advancement in the motorbike production market.

Motorcycle Parts New Zealand Specialists Things To Know Before You Buy

In addition, you have full control over the look of the elements, even to the minute information. Sometimes, motorcyclists may determine to improve their ride by mounting aftermarket components or changing the bike's transformation. Once more, computer system numerical control (CNC) machining is one of the most useful approach. Upgrades may be of any kind of form and design you desire.

Unknown Facts About Motorcycle Parts New Zealand Specialists

CNC machining may be used to make almost all of a motorcycle's steel and plastic parts. To proceed, we'll review numerous machined components for motorbikes.

Milling treatments are made use of to acquire the desired degree of wheel modification. One more element of the bike that might be customized is the tires.

Get This Report on Motorcycle Parts New Zealand Specialists

When it concerns a lorry (or a motorbike), one of the most important element is the engine. Numerous people mention it as the "heart" of the vehicle. On the various other hand, the camshaft, the cylinder head, and the pistons have a tendency to be detailed and require styles with a high level of accuracy.

Lighting is another complicated facet of personalization. Use only high-quality items, nonetheless, given that these lights are important for the safety and security of motorcyclists and other chauffeurs or individuals when driving, especially during the night. Bike fronts lights have three primary components: the light bulb, or light, the lens, and the housing. In specific, we tailor the lens and the real estate.

Milling processes with a flawless finish would result in the lenses having a reflective quality that is similar to that of a mirror. The cover, on the other hand, is not composed of fragile materials; rather, it is constructed out of hard polymers that can be machined into even more complex patterns.

The Of Motorcycle Parts New Zealand Specialists

Motorcycle makers typically cast these parts, yet just for the manufacturing of bespoke parts. Machining on 5 axes in today's globe is the methods by which any style form may be understood.

Select Runsom for your tailored bike parts! We have the ability to make complicated and trendy components making your motorcycle matchless.

Below are a couple of instances of steels commonly made use of in bike part you can try these out machining. Light weight aluminum is the main material used by companies specializing in producing custom motorcycle components to develop many of these components - Motorcycle Parts New Zealand Specialists.

Zinc refers to another steel that is very light in weight and has terrific machining top qualities as a result of its high mechanical toughness. This product may be formed into virtually any form and keeps its measurements well. Even mission-critical components that require a high degree of accuracy may benefit from their usage.

The Best Strategy To Use For Motorcycle Parts New Zealand Specialists

An additional steel that sees heavy usage in the manufacturing of CNC-customized parts is magnesium. It is among the lightest metals that are now obtainable and has outstanding machinability functions and toughness commensurate with its low weight. One of the disadvantages of magnesium is that its dirt might easily ignite.

As a result of its superior machinability and weldability, stainless-steel is an alloy that is particularly appropriate for CNC processes. They have excellent deterioration resistance and a high aesthetic allure. Their most typical use in generating different motorcycle elements is fasteners, such as screws and bolts. Their reduced sensitivity to oxidation and rust makes them ideal for this use.

Some Known Details About Motorcycle Parts New Zealand Specialists

It seems that CNC turning and milling are the foundational processes. In addition, it calls for maintaining bars of product, most usually plastic or steel, in placement and then twisting a reducing device to remove areas of the material as the product is transformed.

These techniques are similarly crucial and create parts with high precision and consistent quality. The processes help enhance the overall high quality of the machined motorbike elements.

The Facts About Motorcycle Parts New Zealand Specialists Uncovered